We understand the drying needs of our customers, which vary by location and application. As a result, the submersible range we supply is developed for the applications of drainage (D) and of sludge (S). These applications require pumps specifically designed for handling corrosive and abrasive media and their solid contents.

All Atlas Copco Brand Weda models are built to last, with their aluminum and stainless steel construction. Most of our submersible pump models can be easily repaired or even refurbished.

WEDA D04N À D10N

- Suction et pressure : 2’’

- Max flow : Up to 119 gpm

- Max pressure: Up to 53.3 inch

- Max solid : 0.18’’

- Power : Available in 1 or 3 phases

- Hp : Up to 1.3 hp

- Material : Aluminum and stainless steel

- Caracteristic : perfect for small job

WEDA D30L À D100N

- Suction et pressure : from 3 to 10’’

- Max flow : Up to 6100 gpm

- Max pressure : Up to 325 pi.

- Max solid : 0.47’’

- Power : Available in 1 or 3 phases

- Hp : Up to 84 hp

- Material : Aluminum and stainless steel

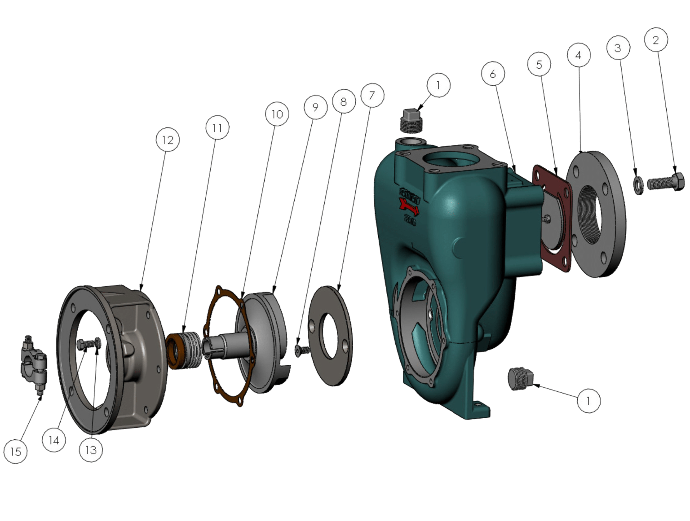

- Caracteristic : asy repair kit (quick install)

- Many parts available and refurbishing also

see brochure

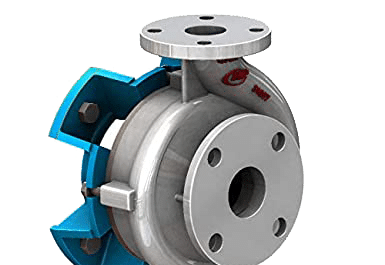

SLUDGE PUMPS

WEDA mud pumps can handle thick, soft and wet sludge or other similar viscous mixtures of liquids and solids, especially the product of an industrial or refining process..

- Suction et pressure : 2" to 4’’

- Max flow : up to 420 gpm

- Max pressure : Up to 100 inch

- Max solid : 2’’

- Power : Available in 1 or 3 phases

- Force : Up to 9.2 hp

- Material : Aluminum and stainless steel

- Caracteristic : asy repair kit (quick install)

- Very light pump

See brochure

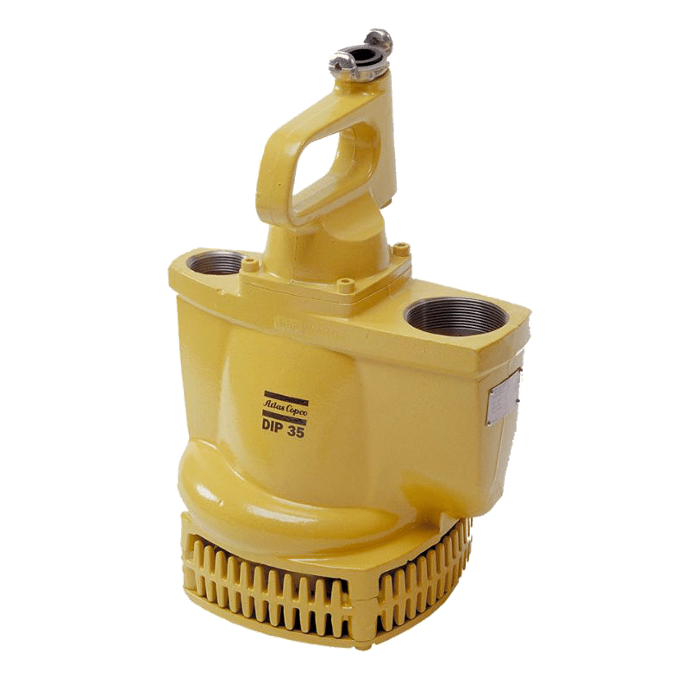

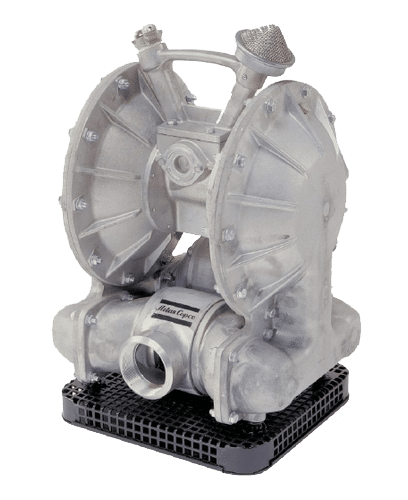

PNEUMATIC SUBMERSIBLE PUMPS (DIP AND DOP)

DIP centrifugal pumps can be designed to suit multiple operations. With a simple change of thruster and intake ring, you can adjust the desired capacity and height. That means you get a three in one solution. The DIP is designed to handle relatively clean low viscosity liquids such as water and coolants.

- Max flow : from 174 to 443 gpm

- Pression max. : from 82 to 193 inch

- Capacity : 148 cfm @ 87 psi

- Material : Cast iron with stainless steel propeler

- Caracteristic : Pneumatique centrifugal

When the going gets tough, the toughest get a DOP diaphragm pump. They are designed for the most polluted and viscous fluids, as well as for highly abrasive and flammable fluids.

- Max flow : 110 gpm

- Max pressure : 193 inch

- Capacity : 72 cfm @ 87 psi

- Material : Aluminum

- Caracteristic : Pompe submersible à diaphragme

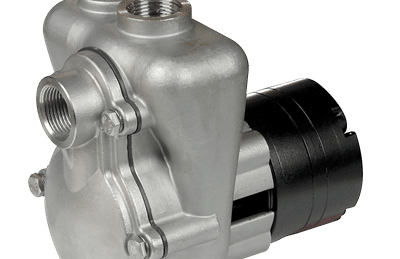

HYDRASUB

This model of submersible pump is rather particular by its hydraulic supply, which makes it a rare model. It is easy to transport and very light due to its aluminum design. The hydraulics required for its operation vary but do not require significant hydraulic capacity.

- Port : 3’’

- Max flow : Up to 400 gpm

- Max pressure : Up to 108 inch

- Max solid : 0.50’’

- Motor : Hydraulic

- Material : Aluminum

- Caracteristic : Light, easy to transport and corrosion resistant

Pour plus d’info visiter https://www.gardnerdenver.com/en-us/mppumps/submersible-pumps

OTHER MODELS AND PARTS AVAILABLE